China OEM Interruptor Manufacturers – Silver Electrolytic Copper Expulsion Fuse – Holley Detail:

Specifications

|

Product Type |

|

EXPULSION FUSE CUT OUT, 27 kV, 150kVBIL, 100 A 8/12kA, 470mm CREEPAGE DISTANCE |

EXPULSION FUSE CUT OUT, 38kV, 170kVBIL, 100A, 5/8 kA, 660mm CREEPAGE DISTANCE |

EXPULSION FUSE CUTOUT, 27kV, 150kVBIL, 200A, 7.1/10 kA, 432mm CREEPAGE DISTANCE |

|

|

No. |

Features |

Unit |

Value |

Value |

Value |

|

1 |

BASE |

|

|||

| Model |

HV1-27/100-8 |

HV1-38/100-5 |

HV1-27/200-7.1 |

||

| Standard |

ANSI/IEEE C 37.40/41/42 IEC60282- 2:2008 |

ANSI C-37.40/41/42 and IEC60282-2 |

ANSI/IEEE C37.40/41/42 y IEC60282-2:2008 |

||

| Rated Current |

A |

100 |

100 |

200 |

|

| Rated Voltage |

kV |

27 |

38 |

27 |

|

| Minimum Short Circuit Current | |||||

| - Symmetrical |

kA |

8 |

5 |

7.1 |

|

| - Asymmetrical |

kA |

12 |

8 |

10 |

|

| Minimum isolation level: | |||||

| - Impulse withstand voltage (BIL), phase to ground and between phases. |

kV |

150 |

170 |

150 |

|

| - Withstand voltage at power frequency between phases, dry, 1 min. |

kV |

60 |

80 |

60 |

|

| - Withstand voltage at power frequency between phase and ground, in wet, 10s. |

kV |

50 |

70 |

50 |

|

| Insulating porcelain material of the base with high purity alumina compositions (between 94% to 99%) with the addition of vitrifiers. |

Yes |

Yes |

Yes |

||

| Minimum creepage distance (Phase-Earth) |

mm |

470 |

660 |

432 |

|

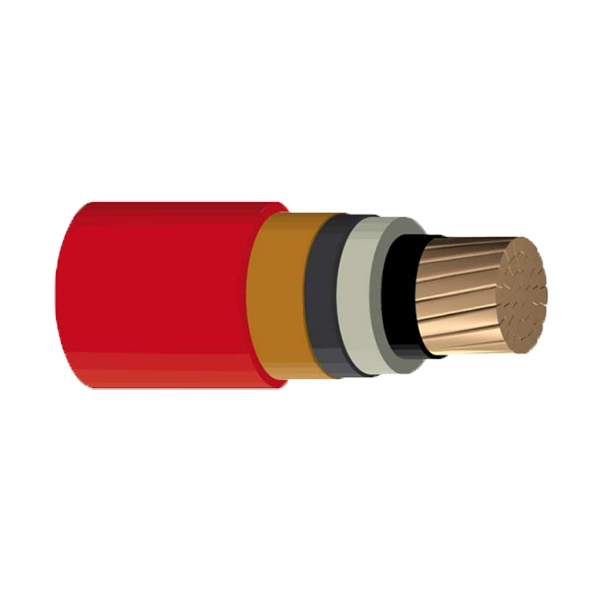

| Contact Material |

Silver electrolytic copper |

Silver electrolytic copper |

Silver electrolytic copper |

||

| - Minimum thickness of the top contact silver layer (tab) |

µm |

15 |

15 |

15 |

|

| - Maximum electrical contact resistance between each terminal and the nearest metal part accessible after contact |

Ohm |

0.000099 |

0.000099 |

0.000099 |

|

| - Upper contact pressure spring with fastening and alignment mechanism |

Stainless steel, grade 304 according to AISI 304, DIN 1.4301 |

Stainless steel, grade 304 according to AISI 304, DIN 1.4301 |

Stainless steel according to AISI 304, DIN 1.4301 |

||

| Terminals material |

Tinned copper |

Tinned copper |

Tinned copper |

||

| -Conductor Range (Diameter) |

mm |

4.11-11.35 |

4.11-11.35 |

4.11-11.35 |

|

| -Terminals for use with copper or aluminum conductors |

Yes |

Yes |

Yes |

||

| -Type of terminals |

Parallel slots, must include bolt, nuts and pressure washers made of stainless steel |

Parallel slots, must include bolt, nuts and pressure washers made of stainless steel |

Parallel slots, must include bolt, nuts and pressure washers made of stainless steel |

||

| Top support channel material |

Galvanized structural steel |

Galvanized structural steel |

Galvanized structural steel |

||

| - Galvanized Material Standard |

ASTM A575 |

ASTM A575 |

ASTM A575 |

||

| - Galvanizing Standard |

ASTM A153 |

ASTM A153 |

ASTM A153 |

||

| - Minimum average thickness |

µm |

86 |

86 |

86 |

|

| Minimum opening angle |

120° |

120° |

120° |

||

| Minimum number of mechanical operations guaranteed |

No. |

200 |

200 |

200 |

|

| Minimum mechanical resistance of the horn for load operation |

daN |

200 |

200 |

200 |

|

| Dimensions (See Figure 1) | |||||

| L |

mm |

704 |

842 |

704 |

|

| M |

mm |

409 |

431 |

409 |

|

| N |

mm |

476 |

567 |

476 |

|

| P |

mm |

72 |

82 |

72 |

|

| Q |

mm |

131 |

147 |

131 |

|

|

2 |

FUSE HOLDER TUBE | ||||

| Features | |||||

| - Standard |

ANSI/IEEE C 37.40/41/42 |

ANSI/IEEE C 37.40/41/42 |

ANSI/IEEE C 37.40/41/42 |

||

| - Rated voltage |

kV |

27 |

38 |

27 |

|

| - Rated current |

A |

100 |

100 |

200 |

|

| - Minimum symmetrical/asymmetrical short-circuit current |

kA |

8/12 |

5/8 |

7.1/10 |

|

| - Internal diameter range | |||||

| - minimum |

mm |

11.1 |

11.1 |

17.5 |

|

| - maximum |

mm |

18 |

18 |

23 |

|

| - Length (allowable range) |

mm |

375±3 |

466±3 |

375±3 |

|

| - Metal parts of joining with the base |

Cast Bronze |

Cast Bronze |

Cast Bronze |

||

| - Fuse holder tube cover (top contact) |

Silver electrolytic copper, with a minimum thickness of 8 um |

Silver electrolytic copper, with a minimum thickness of 8 µm |

Silver electrolytic copper, with a minimum thickness of 8 µm |

||

| - Eye hook for pole operation |

Cast Bronze, with minimum mechanical resistance of 200daN |

Cast Bronze, with minimum mechanical resistance of 200daN |

Cast Bronze, with minimum mechanical resistance of 200daN |

||

| - Fuse holder tube material. |

Fiberglass with internal coating in moisture-proof vulcanized fiber |

Fiberglass with internal coating in moisture-proof vulcanized fiber |

Fiberglass with internal coating in moisture-proof vulcanized fiber |

||

| - Fuse holder opening and closing mechanism (fuse holder base) |

to avoid fuse holder tube un-alignment greater than 15mm |

to avoid holder tube un-alignment no more than 15mm |

to avoid fuse holder tube un-alignment no more than 15mm | ||

| Suitable for chicote fuses with removable head (Arc shortening rod) |

Yes |

Yes |

Yes |

||

|

3 |

FIXING ACCESSORIES | ||||

| - Type of fixation |

Type B, according to ANSI/IEEE C37.42 |

Type B, according to ANSI/IEEE C37.42 |

Type B, according to ANSI/IEEE C37.42 |

||

| - Material |

Galvanized Steel |

Galvanized Steel |

Galvanized Steel |

||

| - Material standard |

ASTM A575 |

ASTM A575 |

ASTM A575 |

||

| - Galvanizing Standard |

ASTM A153 |

ASTM A153 |

ASTM A153 |

||

| - Minimum average thickness |

µm |

86 |

86 |

86 |

Product detail pictures:

Related Product Guide:

Assume full responsibility to meet all demands of our clients; achieve continuous advancements by promoting the growth of our clients; become the final permanent cooperative partner of clients and maximize the interests of clients for China OEM Interruptor Manufacturers – Silver Electrolytic Copper Expulsion Fuse – Holley , The product will supply to all over the world, such as: Mexico, Yemen, America, Our company now has many department, and there have more than 20 employees in our company. We set up sales shop, show room, and product warehouse. In the meantime, we registered our own brand. We've got tightened inspection for quality of product.

Superb technology, perfect after-sales service and efficient work efficiency, we think this is our best choice.